Comprehending Converter Failure: Indicators, Triggers, and Solutions

Introduction

In the world of machines, converters participate in an essential function. They are actually essential in numerous documents, from refrigeration devices to air conditioning systems and also even in commercial methods. Nonetheless, like any mechanical part, compressors are subject to failing. Recognizing converter breakdown-- its indications, creates, and also remedies-- is actually necessary for any individual operating or even preserving these equipments. This extensive quick guide will definitely discover every element of compressor breakdowns to aid you decrease recovery time and enhance efficiency.

Understanding Compressor Failure: Indicators, Reasons, as well as Solutions

What is actually a Compressor?

Before scuba diving into the complexities of converter failing, it is actually essential to understand what a compressor is. A converter is a gizmo that increases the tension of a gas by decreasing its own loudness. Converters locate functions in numerous sectors including heating and cooling (Heating System, Air Flow, and Air Conditioning), vehicle air conditioning units, and also refrigeration units.

Types of Compressors

Each type possesses distinct qualities and also uses customized to certain needs.

Signs of Compressor Failure

Recognizing the early signs of compressor failure can conserve time and money on repairs. Below are actually some popular red flags:

1. Uncommon Noises

- Clanking: Often shows loosened components.

- Squealing: Might symbolize deteriorated bearings.

- Hissing: May suggest cooling solution leaks.

Tip: Routine upkeep may assist detect abnormal audios early.

2. Decreased Efficiency

If you see a decline in efficiency-- like longer running opportunities or lessened outcome-- it might show a hidden problem with the compressor.

3. Recurring Cycling

When the converter activates and off extra often than usual, this may be due to overheating or electric issues.

4. Overheating

Excessive heat can easily bring about premature failure. If your compressor feels very hot to touch or journeys circuit breakers regularly, it costs investigating.

5. Oil Leaks

Oil leakage around the converter can easily indicate wear and tear or even internal damage.

Causes of Compressor Failure

Understanding the factors responsible for converter failures is important for helpful repairing and also protection strategies.

1. Lack of Maintenance

Neglecting routine upkeep can easily lead to different troubles:

- Dirty filters

- Insufficient lubrication

- Wear-and-tear on components

Regularly arranged upkeep can alleviate these dangers significantly!

2. Power Issues

A questionable power source or faulty wiring may weaken your compressor's function:

- Voltage spikes

- Poor connections

- Incorrect electrical specifications

3. Refrigerant Problems

Improper refrigerant levels-- either a lot of or even insufficient-- may severely have an effect on performance.

4. Technical Failures

Wear-and-tear on elements like shutoffs or even pistons may trigger notable breakdowns over time.

5. Environmental Factors

Extreme temps or even humidity amounts may influence your converter's capability:

- Overheating during the course of summertime months

- Freezing health conditions causing ice buildup

Diagnosing Compressor Breakdown: A Bit-by-bit Guide

Diagnosing a failing compressor demands methodical repair:

Step 1: Gather Information

Before jumping into action, acquire all relevant records regarding working past history and any kind of uncommon situations leading up to the breakdown indicators observed.

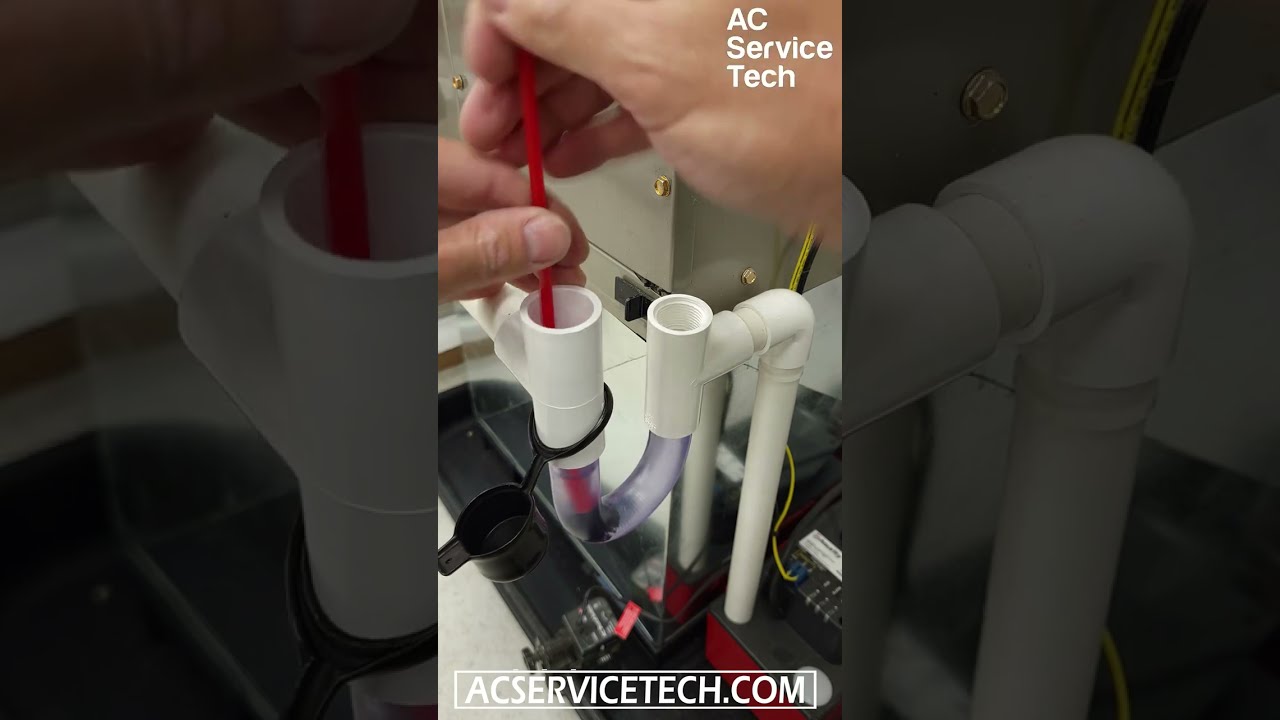

Step 2: Conduct Visual Inspection

Check for apparent signs like oil leaks or broken components that could possibly offer ideas concerning the problem at hand.

Step 3: Evaluate Efficiency Metrics

Look at functionality metrics like pressure readings and temperature degrees contrasted to conventional operating conditions.

Step 4: Examination Electric Connections

Make sure all power hookups are actually safe and secure; check voltage levels for variances that can impact operation.

Step 5: Determine Refrigerant Levels

Ensure that cooling solution amounts are actually within satisfactory arrays depending on to maker specifications.

Solutions for Compressor Failing: Repair Work vs Replace

When dealt with a losing big converter, one need to determine between repair and substitute based upon numerous elements:

1. Age of the Unit

A system nearing its end-of-life might certainly not necessitate expensive fixings when substitute is actually more inexpensive in the long run.

2. Seriousness of Damage

Minor issues might be actually repaired with simple repair services like replacing gaskets or seals; having said that, considerable damages may demand total replacement.

3. Cost Analysis

Evaluate repair service costs versus replacement prices while considering electricity efficiency gains coming from more recent models-- occasionally investing in brand new innovation spends off!

FAQs

Q1: What prevail indications that my air conditioning compressor is actually failing?

Common signs consist of uncommon noises, decreased performance, constant bicycling, overheating, as well as oil leaks.

Q2: Exactly how usually should I sustain my compressor?

Regular maintenance must happen a minimum of once a year however might need to have even more regular interest based on use patterns.

Q3: May I fix my own compressor?

While minor repair work may be feasible along with do-it-yourself capabilities, substantial concerns often call for professional expertise.

Q4: Exactly how perform environmental elements affect my compressor?

Extreme temps can easily bring about getting too hot or icy conditions that hinder performance.

Q5: What's more economical-- mending or substituting a failed compressor?

It depends on age and harm air+conditioning seriousness; often repair services offer short-term relief while substitute supplies better long-lasting benefits.

Q6: Just how do I know if my problem is power rather than mechanical?

Testing power links for current variances are going to make clear whether power issues are actually providing elements just before delving in to technical assessments.

Conclusion

Understanding converter breakdown-- from its own signs with causes and possible answers-- is actually essential for any individual handling these complex equipments routinely. By acknowledging very early distress signal like unique sounds or even lowered effectiveness while sticking strictly to routine maintenance timetables are going to certainly efficient A/C units not merely prolong equipment life expectancy however likewise ensure optimal operational functionality! Whether you're faced with small quirks requiring stopgaps or even deeper issues requiring experienced assistance-- you currently possess the understanding required for efficient troubleshooting! Don't hesitate; take practical measures today!

This post functions as a reliable source including essential information about comprehending converter breakdowns comprehensively!